A total solutions company

specializing in materials and coatings

DEERS SEDA is a total solutions provider for coatings to the automobile and general industrial markets.

As a flexible organization, DEERS SEDA focuses on the export, import, and domestic distribution

and manufacturing of the raw materials, electronic materials, and bio-products on which the chemical industry is based.

DEERS SEDA strives to create corporate value for sustainable growth and expand its businesses

based on professionalism and imagination while responding to changes in the future business environment through innovation.

DEERS Company instruction Download

DEERS Company instruction Download

DEERS Company instruction Download

Business Areas

Trading

Trading

DEERS SEDA provides competitive and stable one-stop import service to its subsidiaries,

including NOROO Paint, DEERS i, DEERSM, NOROO Chemical, NOROO Automotive Coatings, NOROO BEE Chemical, and NOROO Coil Coatings.

To address unavoidable contingencies such as price hikes or inventory shortages, we are always working to develop alternative raw materials.

- 1.Import Services

- 2.Export Services

- 3.Regulatory Management Services (regarding chemical raw materials)

Sales

Sales

We focus on ensuring a consistent supply of chemical raw materials from leading providers at home and abroad, and also on developing new products and markets in new business fields.

We provide a reliable supply of top-quality chemical raw materials at competitive prices sourced from Europe, North America, Japan, China, and India, as well as through exchanges with leading producers around the world.

We will continue to supply chemical raw materials that top the fiercely competitive global market.

With our accumulated experience, information, and know-how, we are committed to going beyond short-term sales and marketing to create value for the present and future of all our partners.

- 1.Import and Sales

- 2.Overseas Marketing of High-quality Products

- 3.Development of New Raw Materials

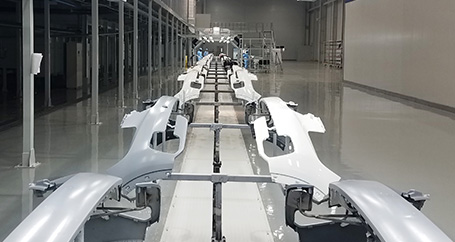

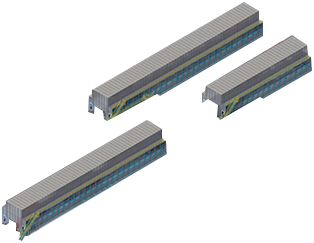

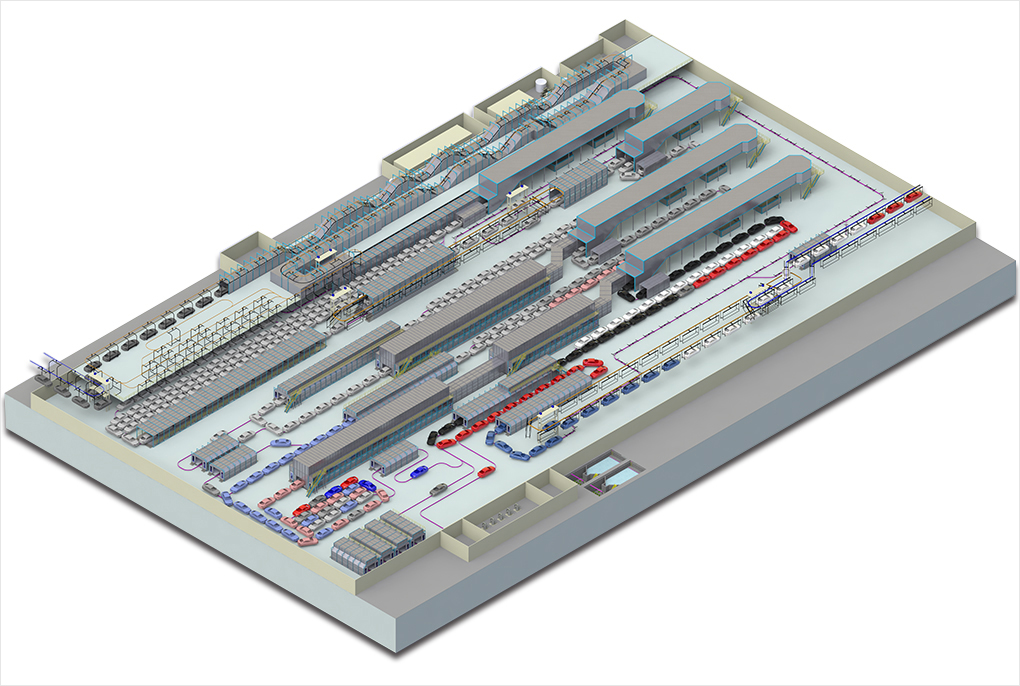

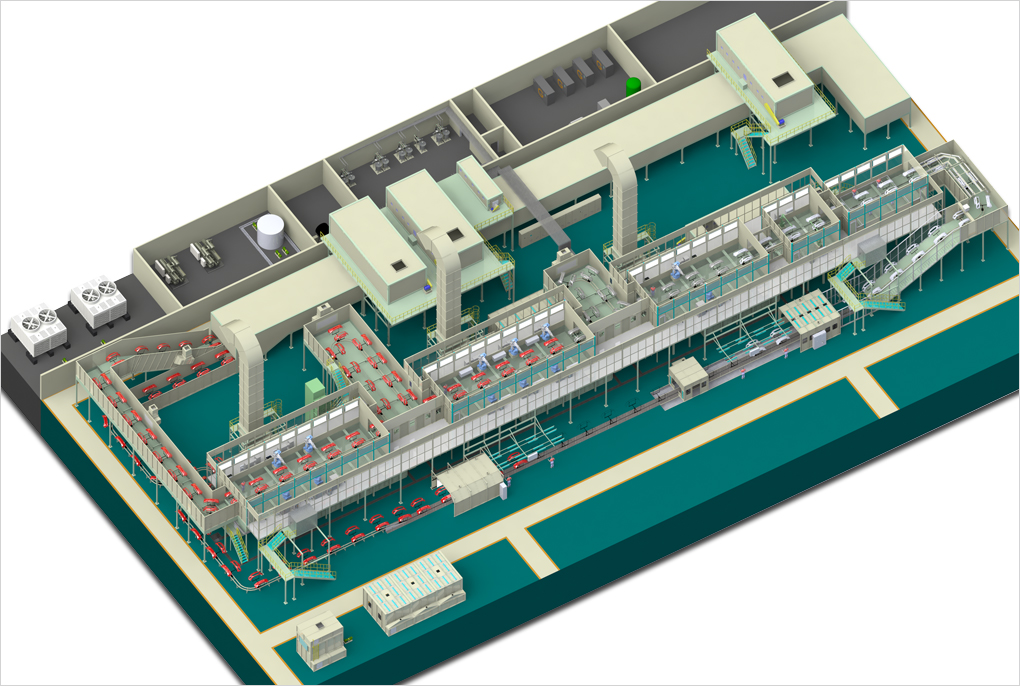

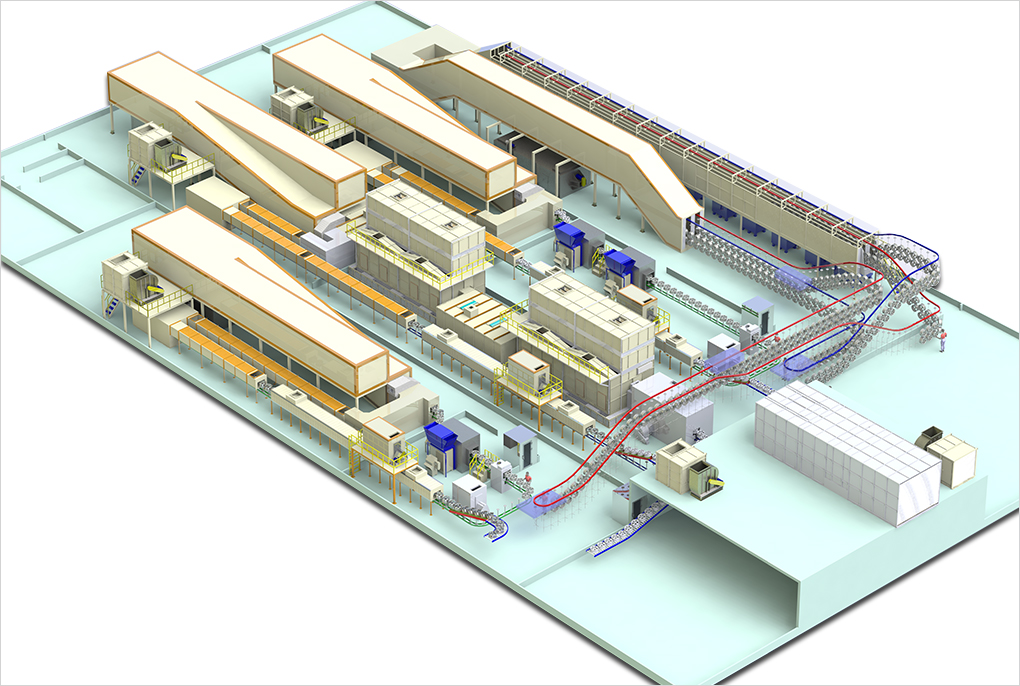

Coating facility

Coating facility

We have long been accumulating core coating facility technology and are constantly pursuing its innovative development.

Based on our decades of experience and acquired technology, we provide our customers with full turn-key services for designing, assembling, installing and operating facilities. Lastly, we continue to pursue energy conservation through improved facility efficiency.

Automobile Industry

- Automobile Painting Line

- Pretreatment System

- Electro Deposit System

- Spray booth & A.H.U System

- Bake Oven

- Cooling

- P.C.S

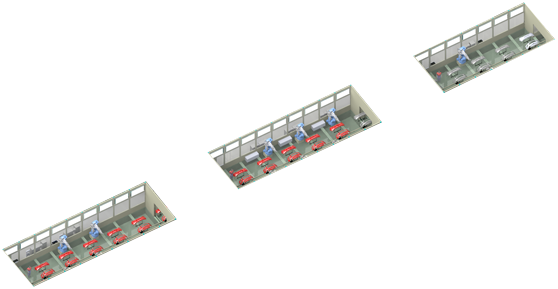

- Robot System

- Environmental Facilities

General Industry

- Bumper Painting Line

- Wheel Painting Line

- Pretreatment System

- Electro Deposit System

- Spray booth & A.H.U System

- Bake Oven

- Cooling

- P.C.S

- Robot System

- Environmental Facilities

Clients

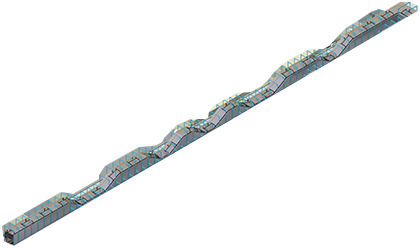

Pre-treatment System

For the pretreatment of painting, degreasing and phosphate coating on the steel surface are performed. Pretreatment enhances anti-rust and paint adhesion performance, and is so important process as determines the final painting quality.

We can provide the next-generation revolutionary equipment. We will offer optimized process and will proceed the design following the concept that the energy consumption shall be minimized.

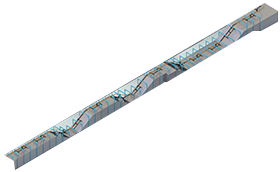

Electro deposit system

We provide our paint system for electrodepositing lines that achieve high quality and energy conservation. Our flow circulation system for electrodepositing tanks has been introduced in many lines. Furthermore, our multi-stage washer systems offer a high paint recovery rate using UF membranes (ultra filter) or RO membranes (reverse osmosis).

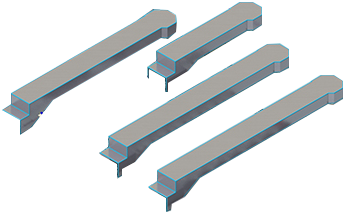

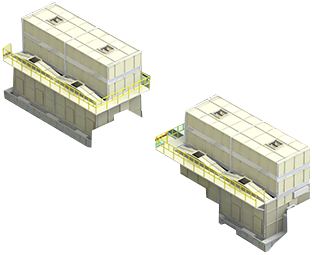

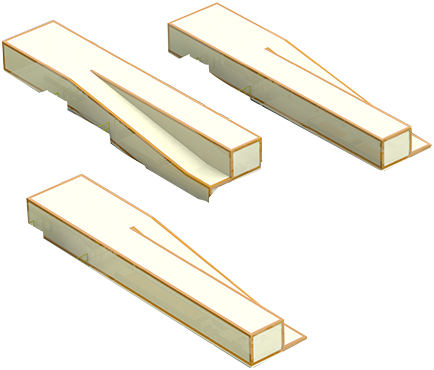

Drying Oven system

We can provide ovens in various types, such as various hot air discharge methods, different heating systems, exhaust abatement systems(TO / RTO), tunnel configurations etc. This great variation enables us to offer an optimized system according to your budget, environmental regulations, restrictions of the building, etc.

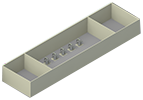

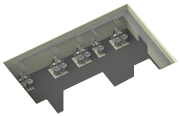

Paint feeding system

A paint feeding system is the most vital system within a painting plant. Approaching the implementation from our customer's point of view, we provide the most suitable systems for the different paints in use, keeping in mind the water and solvent systems and the level of viscosity.

We can offer wide range devices according to the various conditions as follows. (waterborne/solvent borne)

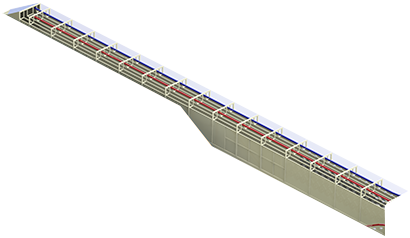

Paint Booth & AHU system

In the paint shop, the booth is the most important equipment where the paint is applied to the job. The paint booth and the air supply unit consume approximately 60% of the energy in the entire paint shop. Therefore the performance of the equipment has a large effect on the quality and energy performance of the paint shop as a whole.

Frame Plasma System

Treatment of the surface with the plasma of a flame is known to impart Oxygen into the surface molecular layers of the substrate.

In so doing, it increases the surface energy, improving the adhesion qualities and provides an ideal surface for further processes such as painting.

Auto Deionized System

Auto deionized system takes a customized and comprehensive approach to total ionization. Proper grounding procedures can efficiently neutralize charges on conductors, but only ionization can eliminate harmful charges on isolated conductors and insulative materials such as plastics.

Paint booth & AHU System

Spray booth is paint mists are discharged systematically through a vertical air conducting system.

We are offers all the application, spraying and air flow components are exactly designed for the different temperature sensitivities of the respective workpieces.

Drying Oven System

The liability of providing poor quality coating finish could range from re-coating your product to the replacement of all the products damaged.

The only way to totally manage the risk is to be in total control. It means investing in a proper drying oven to start with.

Paint Feeding System

Paint feeding system A paint feeding system is the most vital system within a painting plant. Approaching the implementation from our customer's point of view, we provide the most suitable systems for the different paints in use, keeping in mind the water and solvent systems and the level of viscosity.

We can offer wide range devices according to the various conditions as follows. (waterborne/solvent borne).

Pre-Treatment System

The chemical and water for surface conditioning are no longer required, which brings reduced equipment total length and lower waste water treatment costs.

And we have advanced multistage pretreatment systems are perfectly suited for both batch and continuous operation. These perform a through cleaning of all metal parts to be processed, and provide superior corrosion protection.

Powder Coating System

We are provides solutions for complete powder coating systems that are modular in design.Powder booths are offered cyclones or cartridge type powder recovery systems ensure clean and safe work environment.

Efficient powder recovery & recycling systems ensure higher performance.

Wet Spray Booth System

Various range of industrial paint booths is based on a modular concept. This concept enables each booth to be customized to suit any specific requirement. The size of the Booth is determined by the size, shape to be coated.

Booths are designed, engineered and built to comply with exacting.

Drying Oven System

Oven is two types of ovens, dry-off ovens after pretreatment and drying ovens after painting.

According to the material of the work, production throughput, layout restrictions and so on, there are further more varieties. We provide the most suitable ovens with high qualities and low operating costs based on experiences.

(주) 디어스 세다

- 주소13929 경기도 안양시 동안구 동편로 54-11, 9층

- 케미칼 사업부 TEL031.340.0800

- 도장설비사업부 TEL031-340-0866

- 케미칼 사업부 FAX031-340-0899

- 도장설비사업부 FAX031-340-0880

- Emailymkim@seda.co.kr

Family Site

DEERS SEDA Co., Ltd.

- 9F, 54-11, DEERS B/D, Dongpyeon-ro, Dongan-gu, Anyang-si, Gyeonggi-do. KOREA

- Sales of chemicals TEL031.340.0800

- Coating facility TEL031-340-0866

- Sales of chemicals FAX031-340-0899

- Coating facility FAX031-340-0880

- Emailymkim@seda.co.kr

Family Site

Copyright (c) 2020 DEERS SEDA Co., Ltd. All Rights Reserved.